Real-time Falling Particle MonitorAPMON

Continuously monitors

fallen and deposited particles

- ISO14644-17

Continuously monitors

fallen and deposited particles

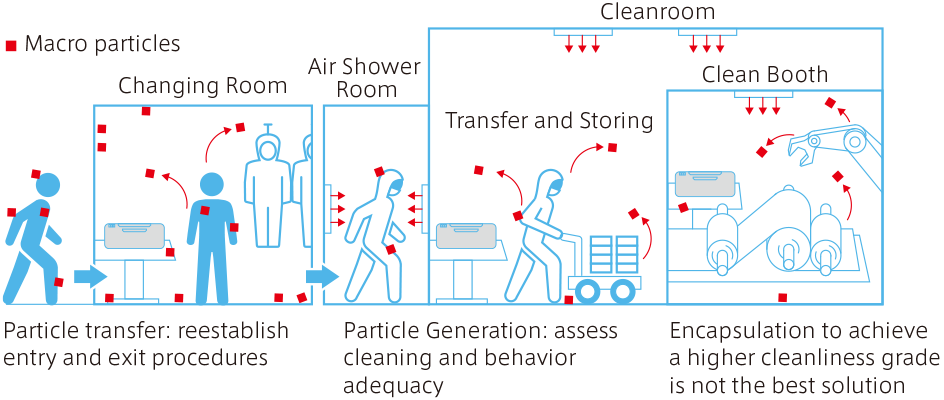

With the demand for a clean manufacturing environment in various industries, controlling particle contamination remains an eternal challenge for many companies. The contamination caused by particle deposition cannot be controlled by air particle counters nor with microscopic analysis. The key to reduce the risk of contamination is to know "when" and "how" the particles generated.

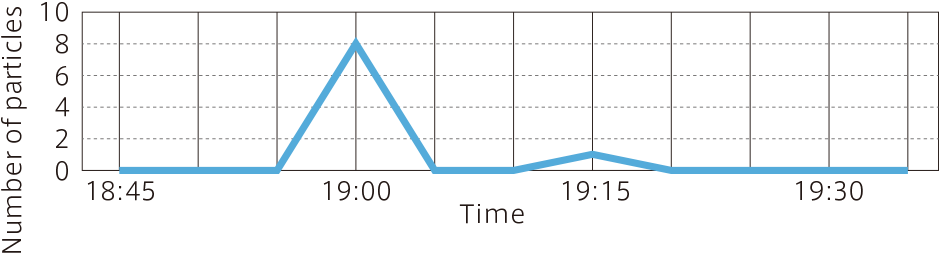

APMON continually monitors the moments of increase in particle generation (particle events). These unwanted events are the result of inappropriate behaviors of personnel, systems, and cleaning.

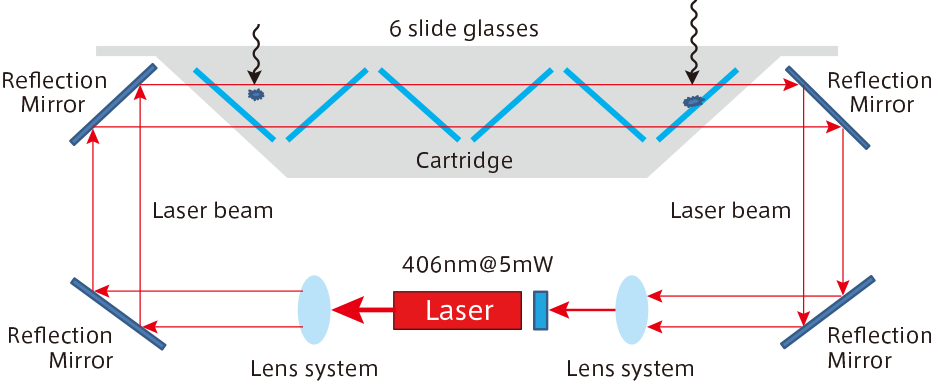

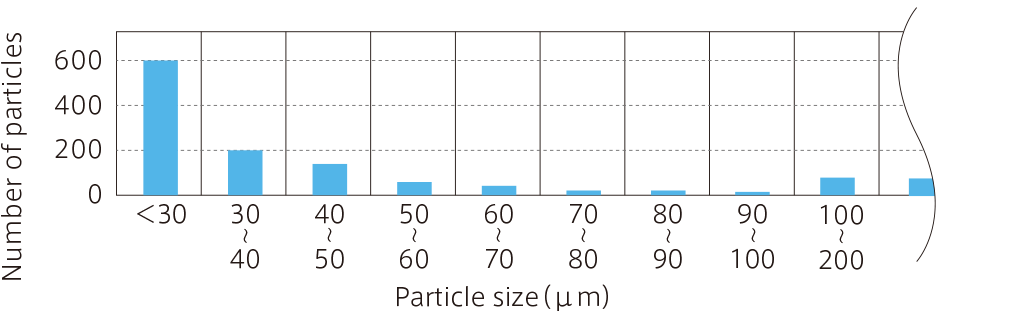

The wavy laser beam diffracted through the particle surface detects its shape from its waveform. The detected and recorded particle is shown as a 3 dimensional image by the diffraction pattern using the Fourier transform method. The result is the particle size distribution of the deposited particles from the previous measurement. (5 minutes ago)

The wavy laser beam diffracted through the particle surface detects its shape from its waveform. The detected and recorded particle is shown as a 3 dimensional image by the diffraction pattern using the Fourier transform method. The result is the particle size distribution of the deposited particles from the previous measurement. (5 minutes ago)

APMON should be placed in close proximity to a manufacturing process to allow for real-time monitoring of depositing macroparticles that are risks to the product quality. By measuring particles of ≥15µm every 5 minutes, it detects “when,” “who/what,” and “how” particle generated.

APMON should be placed in close proximity to a manufacturing process to allow for real-time monitoring of depositing macroparticles that are risks to the product quality. By measuring particles of ≥15µm every 5 minutes, it detects “when,” “who/what,” and “how” particle generated.

| Detectable particle sizes | 15 - 1000µm |

|---|---|

| Detection surface area | 25cm2 (4.2cm2×6) |

| PDR | 99% Confidence interval ±6% (long term) |

| Measuring interval | 5 minutes (with Ethernet connected) |

| Size | 390×80×150mm (15.4×3.1×5.9in) |

| Weight | Approximately 5kg (battery included) |

| Power | Adapter 100-240V AC / 9V DC 550mA or Battery 7.2V / 7.8Ah |

| Batteries | Rechargeable Lithium-ion battery |

| Number of batteries | 2 per sensor |

| Battery Usage time | Approx. 4 days (depending on measuring interval) |

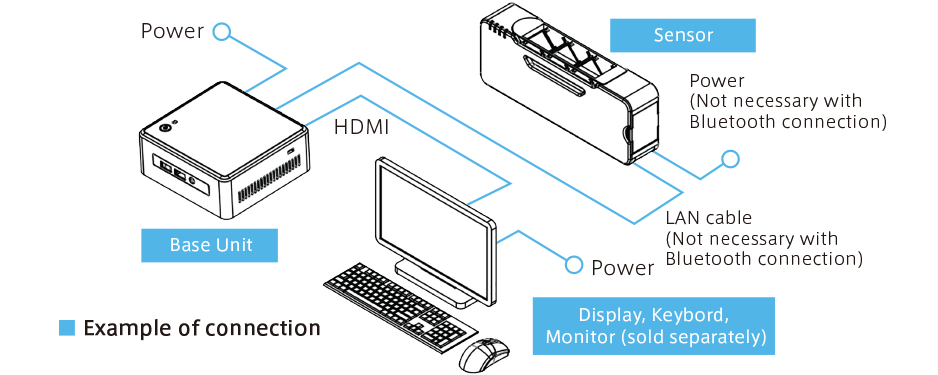

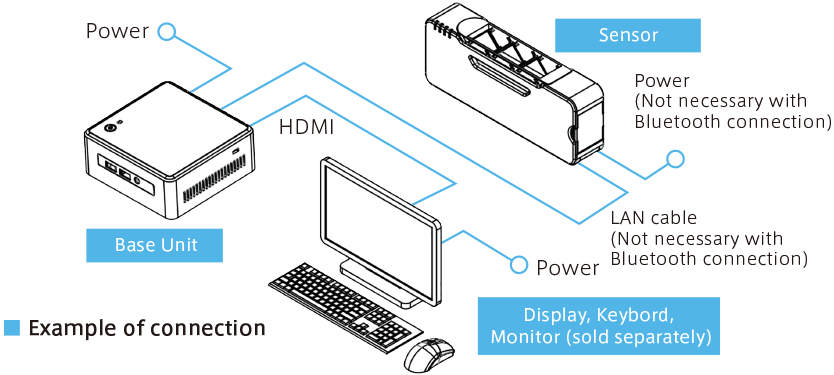

| Communication base unit | Ethernet or Bluetooth 2.0 (approx. 15 - 20m depending on measuring environment) |

| Optical light source | 20mA Laser Diode 406nm |

| Principal | Holographic imaging |

| Laser safety classification | 2m according to IEC60825-1 |

| Calibration | Production approved, once a year |

| Environment (operating) | 10℃ to 35℃ (50℉ to 95℉) 10 to 90% relative humidity, non-condensing |

| Material | Plastic and glass |

|---|---|

| Duration in use | Max. of 3 months, depending on the condition of the cleanroom |

| Size | 254×74×45mm (10.0×10.0×1.7in) |

| Packaging | Packed in two bags in a controlled environment |

| Replacement | Warning by software |

| Maximum number of sensors | 2 |

|---|---|

| Wireless communication | Max. of 2 sensors |

| Batteries / Charger | 〇 |

| USB Data Output (CSV) | 〇 |

| Travel case | 〇 |

| Monitor, Keyboard, Mouse | Optional |

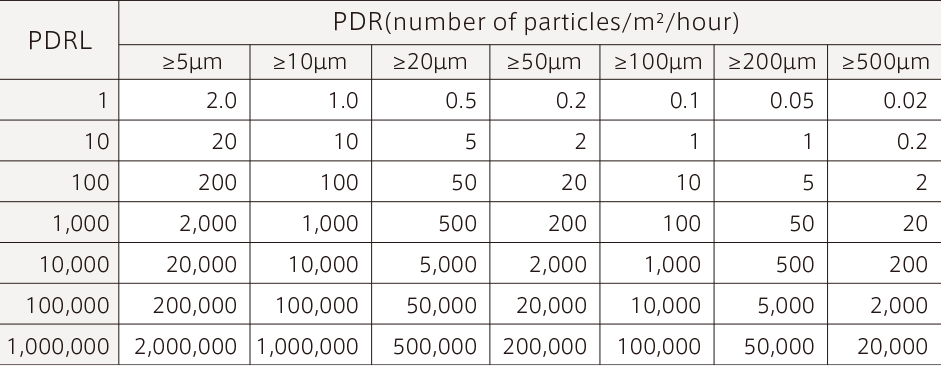

Aside from counting the number of particles for each particle 15 to 1000µm in real-time, APMON calculates the number of accumulated particles over a certain period of time.

PDR = Number of Particles(≥Dµm) / Area(1dm2) / Time(1hour)

The PDR is the rate of deposition of particles onto surfaces and can be calculated as the change of surface particle concentration per m2 during the time of exposure in hours. ISO14644 and other European quality standards recognize PDR as the risk assessment method for monitoring and controlling macroparticles.