Cleanroom Solutions

Cleanroom Observation and Improvement Technology

The misconception of cleanliness in cleanrooms.

Particle counters are unsuitable for measuring particles ≥5µm.

In a manufacturing environment controlled with ISO14644-1 cleanroom classification, very small amount of particles sizes of 0.1 to 5µm (airborne particles) are detected, and particles sizes of more than 5 µm (macroparticles) detect as none or very few. However, when a cleanroom is on operation, many macroparticles can be found on every surface regardless of how clean the air is. Macroparticles cannot be vacuumed by air particle counters as they scatter in the direction of gravity, leaving the risk of contamination undetected. In addition, macroparticles are difficult to remove with airflow or filters. They accumulate and deposit on all surfaces. These particle can only be removed by proper cleaning.

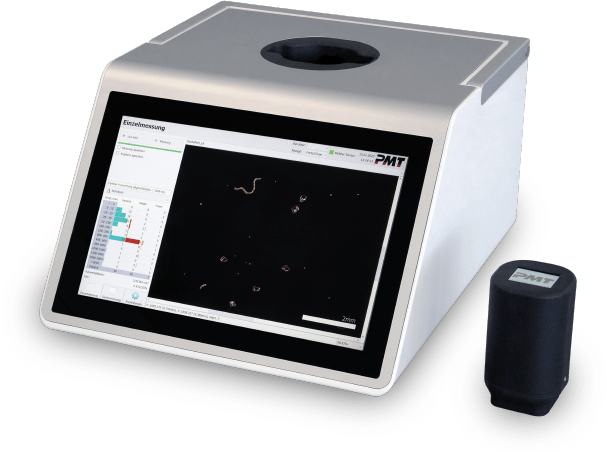

Intechno's Clean Manufacturing Environment Solutions

Contamination mechanisms

Understanding the contamination process...setting an innovative mindset.

Contaminants adhere to vulnerable surfaces of products and environments by two mechanisms: “deposition (fall-out)” and “contact transfer” of particles. The risk level of the two mechanisms correlates to the degree of activities and low surface cleanliness levels in a cleanroom, such as poor execution of cleanroom procedures, unclean machinery, and tools. Therefore, risk control for products and environmental contamination means to control surface cleanliness levels and behaviors.

Observation of risk factors

To control contamination calls for... quantitative assessment

When the product quality is threatened, a sudden urge to monitor the air cleanliness level and to look into a microscope for clues occurs. However, this is not an adequate approach. As we have consulted various companies of different industries, we successfully managed to suppress such an urge for taking idea based measures. Our monitoring technique focuses on measuring the concentration of particles larger than the risk particle size and detecting improper behaviors during operations.

The importance of contamination control demonstration and education

Reducing contamination risks by demonstrating control

Continuously monitoring "surface cleanliness" and "particle deposition" and giving experimental changes to risk factors can identify behaviors of personnel, systems, and cleaning method that is highly effective for reducing unwanted particles. Intechno's consultation and education services encourage companies to take an innovative approach against contamination. Having improved product quality for various global companies, our services have been valued by the top executives of major companies.